Electro-Active Enamel-Coated Dowel Bar

Advanced steel dowel coating prevents concrete failure and extends infrastructure life

Current Dowel Coating Limitations Lead to Concrete Failure

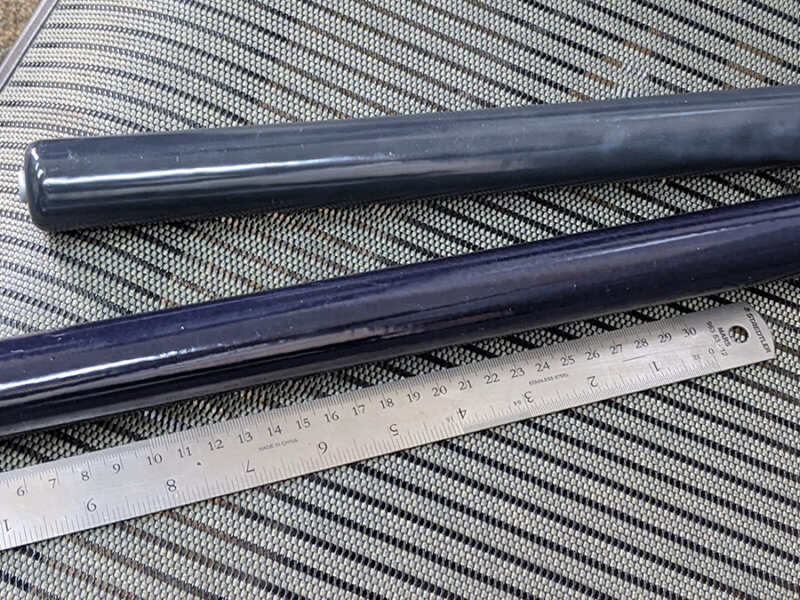

Steel dowel bars join and restrict the movement of concrete slab segments in various construction applications. They embed between adjacent concrete slabs or horizontally spaced within the slabs as joints between adjoining segments.

In current manufacturing processes, the dowels are coated with epoxy or enamel to provide slip and accommodate naturally occurring dowel movement from thermal contraction and expansion. However, such processes result in surface defects that corrode over time, inhibiting dowel movement and expediting concrete slab damage.

Advanced Manufacturing Process Creates Corrosion-Proof Steel Dowels

ERDC has developed an improved design and manufacturing method to ensure defect-free steel dowel surface coatings. This prevents rust buildup and salt corrosion, leading to the eventual cracking and breaking of concrete slabs.

This electroactive design and application technology eliminates enamel coating flaws that lead to rusting and salt corrosion. As rusting occurs over time, the steel can significantly corrode and expand up to six times its original volume, increasing friction between the steel dowel and surrounding concrete. This exerts pressure on the concrete, eventually leading to its failure, resulting in costly repairs and a lower lifespan.

ERDC’s improved technology creates a vastly superior, highly stable steel dowel to create a safer, more durable concrete slab.

Benefits:

- Improved performance: Improved steel dowel coating increases concrete joint strength up to sixfold, resulting in better management of thermally induced movement.

- Higher durability: Concrete slabs are resistant to salt corrosion by the steel dowel’s electroactive design and flawless surface coating, extending their useful life. This is critical in locations that apply salt to roads in winter, in areas exposed to ocean water, and in industrial applications that expose concrete structures to salt.

- Lower maintenance: Lack of rusting and corrosion improves the longevity of concrete slabs, greatly decreasing maintenance needs and costs.

- Reduced cost: Improved design and coating process enhance the strength of concrete slab joints, requiring less steel to reinforce them. The increased lifespan and durability may translate to billions saved in replacement and maintenance costs.

- Safety: Stronger, more durable steel dowels greatly improve concrete slab stability. Reduced distortion and stresses that cause cracking and breaking contribute to the overall integrity and safety of concrete construction.

Applications:

- Roadway construction and repair, including bridges

- Airport runway construction and repair

- Construction and infrastructure components

— Pavement joints

— Concrete slabs

— Structural steel components (rebar, precast concrete)

- Military bases, including roadways, runways, and structures

- Industrial facilities

Patents

- 10711411 (Search patent)